| DUSTIN X DISC TECHNICAL SPECIFICATIONS |

UNIT | 4 Row | 6 Row | 8 Row | |||||

| Fertilizer | Without Fertilizer |

Fertilizer | Fertilizer | Fertilizer | Without Fertilizer |

||||

| Width | mm | 2800 | 2800 | 4000 | 4000 | 5600 | 5600 | ||

| Height | mm | 1600 | 1500 | 1600 | 1500 | 1600 | 1500 | ||

| Length | mm | 2300 | 2300 | 2300 | 2300 | 2300 | 2300 | ||

| Seed Tank Volume | lt | 4*35 | 4*35 | 6*35 | 6*35 | 8*35 | 8*35 | ||

| Fertilizer Tank Volume | lt | 2*160 | – | 2*200 | – | 2*240 | none | ||

| Disc Hole Diameter | mm | 1-6 | 1-6 | 1-6 | 1-6 | 1-6 | 1-6 | ||

| Disc Number of Holes | pcs | Variable | Variable | Variable | Variable | Variable | Variable | ||

| Distance Between Rows | cm | 45-70-75 | 45-70-75 | 45-70-75 | 45-70-75 | 45-70-75 | 45-70-75 | ||

| Distance Row | cm | 1-177 | 1-177 | 1-177 | 1-177 | 1-177 | 1-177 | ||

| Working Speed | km/h | 6-8 | 6-8 | 6-8 | 6-8 | 6-8 | 6-8 | ||

| Required Power | hp | 70-80 | 70-80 | 90-110 | 90-110 | 110-130 | 110-130 | ||

| Weight | kg | 1100 | 900 | 1400 | 1200 | 1650 | 1450 | ||

Pneumatic Deep Seeder – DUSTIN X DISC SERIES

Pneumatic Deep Seeder – DUSTIN X DISC SERIES

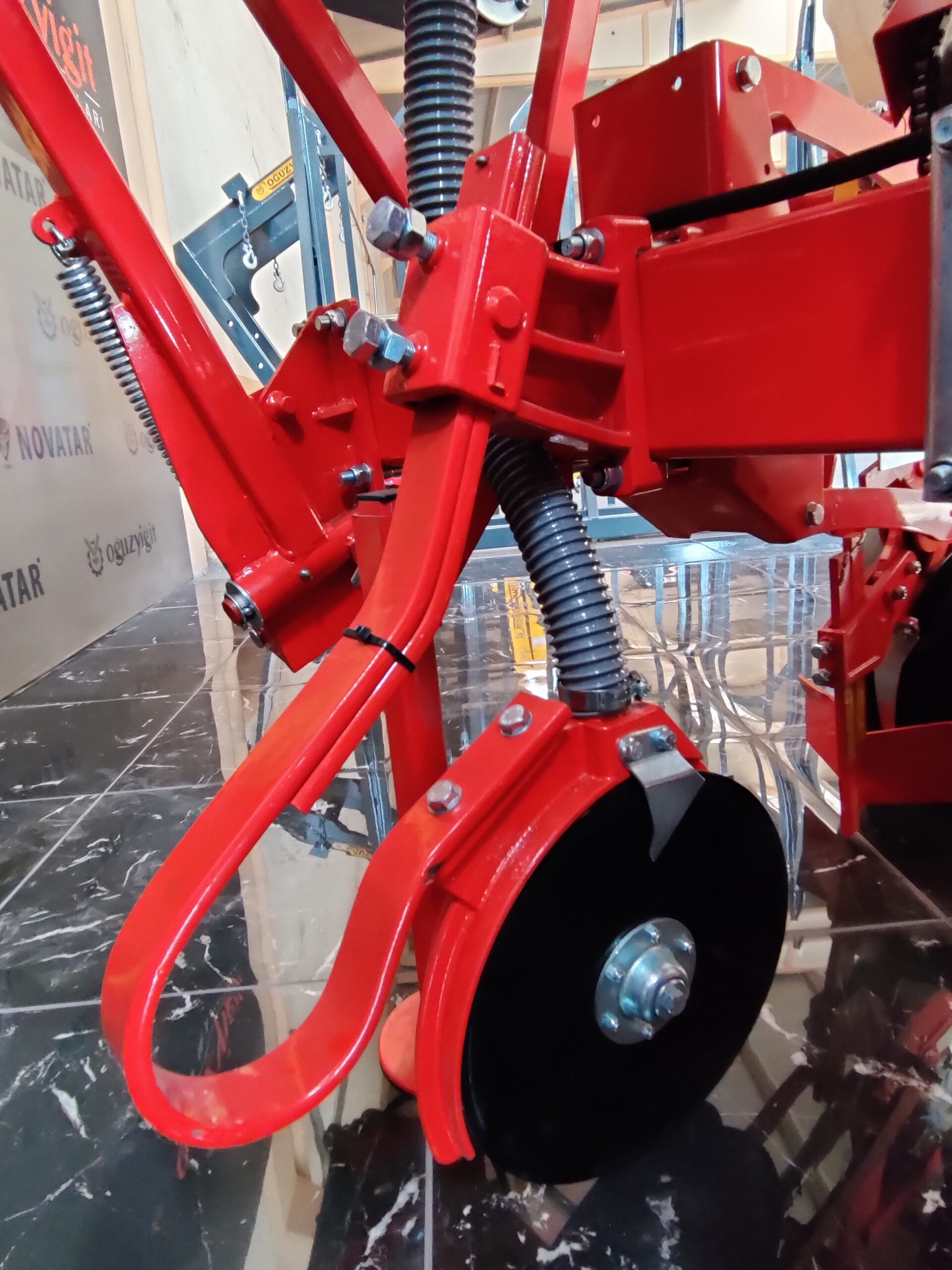

Dustin Disc 6 TLC Series Pneumatic Planter is a precision agriculture implement developed to increase productivity and to ensure accurate seeding. Pneumatic Planter works for all types of seeds, thanks to numerous seed discs available for different crops. Dustin Disc DEEP PLANTER specially developed for low-till techniques, no-till planting and intensive conditions of use. The Dustin Disc DEEP PLANTER is designed for demanding farmers and dealers looking for a versatile precision planter capable of working in difficult and low-till conditions with high-quality planting. It is manufactured with 4-6-8 rows optionally. Seedbed is opened with the help of discs in sowing units.

Due to its heavier chassis, heavy-duty units, and bigger diameter discs, it can operate in fields with processed or semi-processed stem remains thanks to cutter discs attached to the the front side of the chassis and disc type sowing units. Because movement obtained from the wheel is transmitted to sowing units by shaft mechanism, precision sowing can be performed in intra-row distances.

Due to rubber wheels located on both sides of the Sowing Units, precise Depth adjustment can be made in all kinds of soil conditions. V which is located at the rear of the seed unit can be tightened by means of pressure wheels. Pressure applied by the rear pressure wheel and angle can be adjusted by means of spring. V pressure wheels prevent the formation of a duff layer on the soil. Disc type sowing units allow sowing in early temper.